Over the last few decades, technology has driven a significant spurt in the number and variety of construction materials that have become available. Aspiring homeowners can explore multiple options based on utility, aesthetic appeal, budget and quality. While easy access to construction material means more choices it doesn’t necessarily mean the process is easy. It is important to set off on this task equipped with the right information especially because your choices can have long-lasting implications.

In this article, we will look at 11 of the best available & commonly used construction materials for Indian homes. We will also try and explain what should drive your choices based on their advantages and disadvantages.

Mud & Clay

Mud and clay are probably two of the oldest known materials that have been used for construction. While these two are no more used in their most basic form in modern construction they are still the primary constituent in building materials such as bricks, tiles and plastering.

The main advantage of mud and clay building material is that they are natural substances that are found in abundance. They are great binders, easy to mould, cast and work with which is why they are still in use today. Their carbon footprint is significantly less in comparison to steel and concrete and requires lesser processing.

However, when choosing mud or clay composite materials be wary of the quality. These constituents may not be quality controlled and can come from various sources making the quality of the final product inconsistent. Always look for reputed suppliers and ensure you are using them in the right conditions and functions.

Wood

As a construction material wood is so versatile, we can’t imagine a home without it. Wood is a valid option for almost every feature in your home starting from doors, windows, flooring, rafters, facade, walls, etc.

Wood makes for brilliant construction material because of its natural properties – high compressive strength, density, insulation, and in some cases resistance to moisture. Modern manufacturing has been able to enhance these properties further through various methods of treatment. Manufactured wood products and wood composites made with polymers have eliminated some of the biggest disadvantages of wood such as vulnerability to termites, water damage and warping.

While available in abundance and very easily accessible the quality of wood you choose will affect its lifetime in your home. Be it in the furniture or the flooring you must be cautious to choose the best option given the constraints. Wood is also becoming increasingly expensive. It is not a fast regenerating resource and has to be harvested responsibly. If you can factor the costs into your budget, choosing wood in most applications will elevate the aesthetic and natural feel of your home greatly.

Steel & Iron

Steel and iron are common building materials in India. They are typically used for framing and other structural purposes. Steel is an alloy of iron and carbon and has better tensile and compressive properties. Iron doesn’t rust as easily as steel and is often lighter than steel making it a great option in construction

The widest application of steel is in RCC or reinforced cement concrete. Steel is what provides the “reinforcement” to compensate for concrete’s lack of tensile strength. The other major use of steel is in structural members. Structural steel members such as beams and columns come in different shapes and dimensions and reduce construction time significantly.

While steel is best suited for industrial and commercial applications, it is not uncommon in modern homes. Pergolas with sleek structural steel frames, car park structures, staircases, door and window frames, etc are some common applications. But if you need a quick turnaround time for the construction of your home, don’t hesitate to explore concrete encased steel structure frames with sufficient attention to fireproofing.

Concrete & Cement

Second only to water, concrete is the most consumed material in the world. Thus is the importance of concrete. Concrete’s main ingredient is cement, which is used in conjunction with water to achieve the desired consistency. Cement is the binding material added to concrete to give it strength and durability.

There are many advantages of using concrete versus other building materials. The biggest advantage is its durability. Well placed concrete has a lifetime of upto 100 years or even more if you look at historic structures. Apart from having excellent compressive strengths, concrete is also waterproof, fireproof and relatively cheap, as compared to other materials like structural steel.

Cement on the other hand is not just used in concrete, but also in plastering to finish walls, in mortar for bricklaying, laying floors and waterproofing. Other uses of cement include roofing sheets, lining drain pipes and protecting other exposed surfaces prone to harsh conditions and chemicals.

Plastic

Plastic is one of the most versatile materials ever to be invented. It is a common name given to materials made of synthetic polymers. Though it is increasingly posing a threat to the environment it is more because of irresponsible use, and disposal than anything else. The major types of plastics used in construction are acrylics, composites, polyethylene and polyvinyl chlorides(PVC).

While acrylics are used in flooring, cladding, flexible and transparent glass sheets, etc, polyethylene or polythene is used as a temporary cover over concrete and damp-proof membranes. PVC, UPVC and composites are the most common forms of plastics used in construction materials. PVC is used extensively in pipes, fittings, doors, windows, frames and claddings.

Plastics are very durable and do not corrode or rot over time. Since they are synthetic they can be designed specifically with desired physical properties. Some plastic construction materials are designed for strength while other plastics can be designed to provide insulation, flexibility and even aesthetic appeal. The one major drawback of plastic however is that it doesn’t handle heat well and is prone to thermal expansion. Appropriate measures need to be taken to account for this or specifically designed heat resistant plastics needs like unplasticized polyvinyl chloride(UPVC) needs to be used.

Glass

Glass is that one material that when used correctly can elevate the look of your home, while ensuring that your home is well lit and ventilated all the time. Glass is primarily manufactured from sand, limestone, and sodium carbonate.

While the use of glass in construction began with cast glass windows, modern-day use of glass has extended to glazings, fenestrations, skylights and even glass bricks. The colors and patterns that are possible in glass have made it a favorite of designers.

Charming french windows with clear glass panes, color pops of glass panes that give out beautiful reflections, full-height sliding doors which bring the outside into the home are some timeless concepts that use glass effectively.

With time, glass too has developed and is even used as an insulation material. What’s more, glass with specific values of the reflective index, double or triple glazed glass, etc are one amongst popular green building materials.

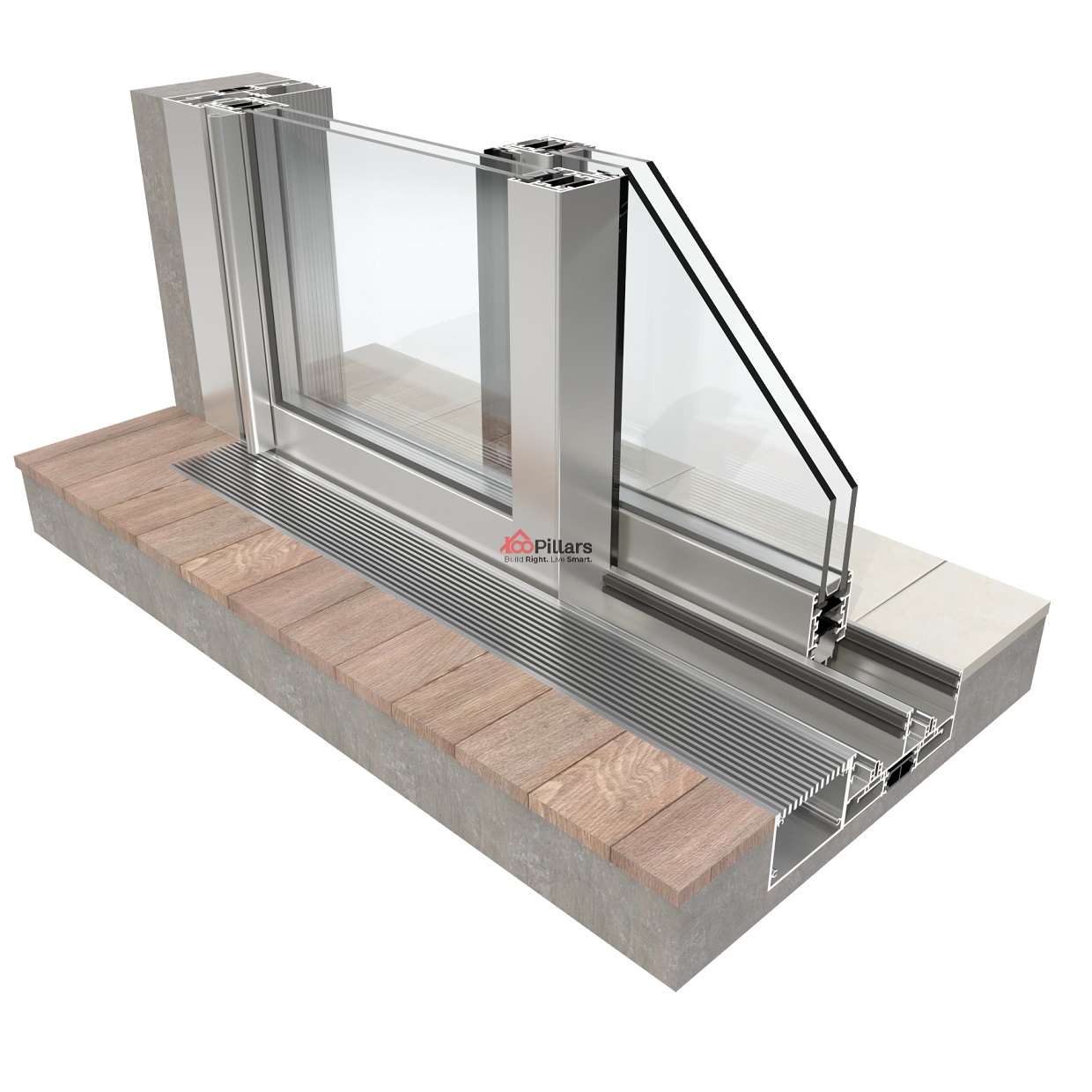

Aluminium & Copper

Aluminium is the second most widely used element after steel. It is generally used in alloy forms to get the required strength it needs as a construction material. It’s lightweight, strength and sleek appearance is what makes it favorable over steel.

While aluminium finds many uses as a construction material in the form of roofing sheets, insulation panels, curtain walling, structural glazing etc, its most common use in Indian homes is in the form of aluminium powder coated frames, mostly for windows and doors.

Ease of installation, longevity and colors available in the market are some factors which has led to these frames almost replacing the traditional wooden window and door frames. Unlike wooden frames, aluminium frames are not prone to expansion or contraction with weather, nor are they prone to pest attacks. All these put together, aluminium aces the list for modern window and door frames, sliding types in particular. Some other uses of aluminium in construction include use as earthing strips, scaffolding ladder material etc.

Copper is also a widely used metal in the construction industry. Durability, ability to withstand extreme weather conditions and its excellent conducting properties makes copper suitable as a construction material. Plumbing systems, electrical wiring, gas pipelines ,flashings to accentuate architectural elements are some common uses of copper in homes.

Fly Ash Bricks

Fly ash bricks are manufactured from cement, sand, fly ash, lime, admixture (generally aluminum paste) and water. They are also known as AAC (Autoclaved aerated blocks) as the manufacturing process involves steam curing the bricks in an autoclave at maximum ambient temperatures ranging between 170 and 215℃.

Fly ash bricks have micro-air entrained within them and thus very low density. Their light weight makes them very easy to transport and handle during construction. The entrapped air gives AAC blocks good insulation properties and fire resistance, thereby reducing energy consumption.

Fly ash bricks have very good compressive strengths (2-7N/mm2), but they are brittle in nature and should be handled with care.

Fly ash bricks have gained popularity quickly amongst builders and home owners due to their widespread availability, textures and colors. Additionally, these blocks also have the advantage of being more sustainable than concrete blocks.

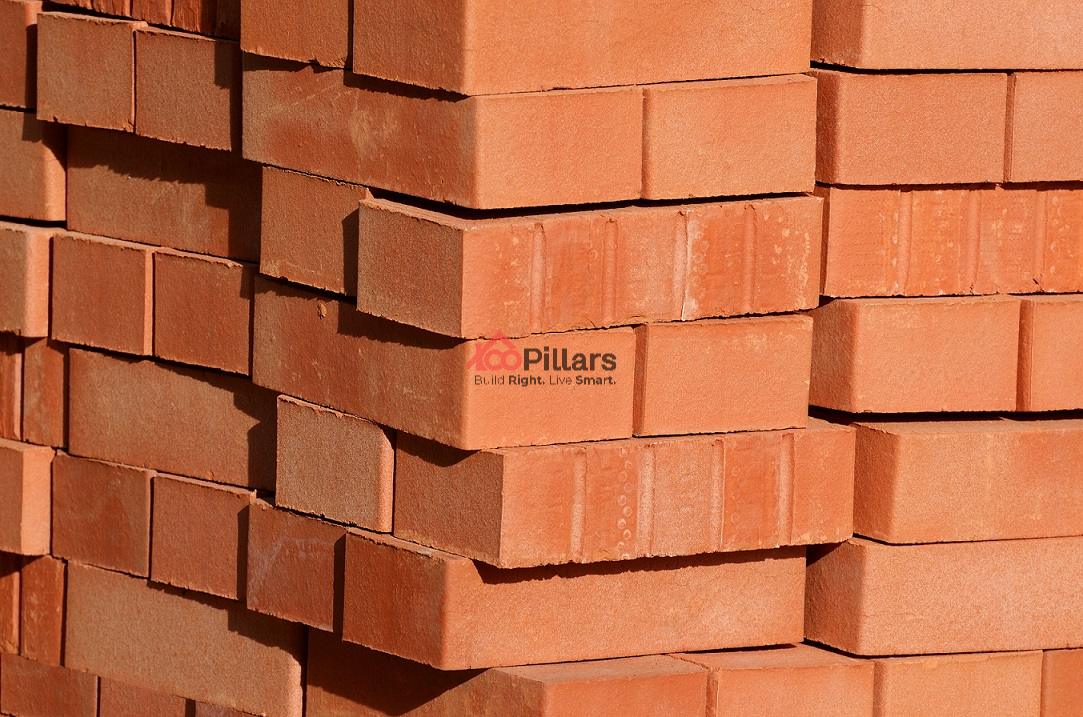

Clay Bricks

As the name suggests, clay bricks are made from clay – suitable soils which are mainly composed of silica (grains of sand), alumina, lime, iron, manganese, sulfur, and phosphates in different proportions. They are the first type of bricks to be used in construction.

Before the advent of concrete bricks, clay bricks were used extensively for walls. But now with different types of brick which have more compressive strength, are lightweight, are waterproof and cost less, the use of clay bricks has faded away.

But you will still see clay brick used in facades, as a cladding material, external floors, landscaping, ovens etc. Clay bricks with their high thermal mass help in keeping the buildings cooler. The use of exposed clay bricks gives a rustic feel to homes giving it a timeless look and feel.

Stone

Naturally occurring stones that are carved to perfection for use in construction is yet another favorite material that brings much depth to designs. Their strength is only an added advantage if you think of the different ways in which stones can be used in the construction of your home.

Right from foundation, walls, floors, cladding, paving, to steps, stones can be literally carved into almost any part of your home. Reclaimed/recycled stones are even used in concrete, which makes it a sustainable option.

The only downside to stones is their weight, which is the heaviest as compared to other materials. But, the colors and patterns in which stones are available make them a great material that can be used to create a solid monochromatic look in modern minimalist homes.

Sand

Sand is an abundantly occurring natural resource that has extensive use in construction. It is formed by the natural weathering of rocks and consists primarily of granular silica. The primary purpose of sand, by itself, and in combination with other materials is to provide body or bulk. It also increases the strength of certain composite materials.

Another major function of sand is to provide a level surface for construction in foundations, landscaping and filling of voids or cavities in parts of the building. Given sand is fluid and can be compacted easily it is easier to spread and level in comparison to stone or gravel while offering the same advantage of strength.

Off late, the construction industry has turned to technology to come up with manufactured sand. This helps prevent the problem of excessive mining of river beds.

M-sand is made from unused fragments of granite or other specific hard rocks which are powdered to the desired size and granular shape. Different types of M-sand are used in specific applications. For example, P-sand or plastering sand which is a type of M-sand is used specifically for plastering allowing for a finer and smoother finish.

Aggregates

While aggregates broadly refer to all coarse material, the more common reference however is to gravel, stone and pebbles that are used in concrete. The most widely used form of aggregate is gravel and used as a filler in concrete to provide both volume and strength. In fact, it is primarily gravel and cement together that provide strength to concrete.

Aggregate, like sand, is also used as a “fill” in voids and cavities but less so because it is more expensive and difficult to level due to its irregular shape. While the quality of aggregate is standard the uniformity of gravel in shape and size is an important factor. It is what makes concrete truly homogenous and ensures that concrete behaves monolithically which is very important.

Conclusion

With so many options available in the market, you can easily feel lost and overwhelmed. Choosing the right material is one thing, but choosing the right material for the right functionality is another. While the above mentioned materials form a very sound list of the most common materials that are used in home constructions, your options are plenty. Make sure that you get in touch with experts who can give you an overview of the latest available options of materials. Experts like 100Pillars with their diverse experience, will not just run you through all available options, but also make sure that you choose the right ones based on your requirements.